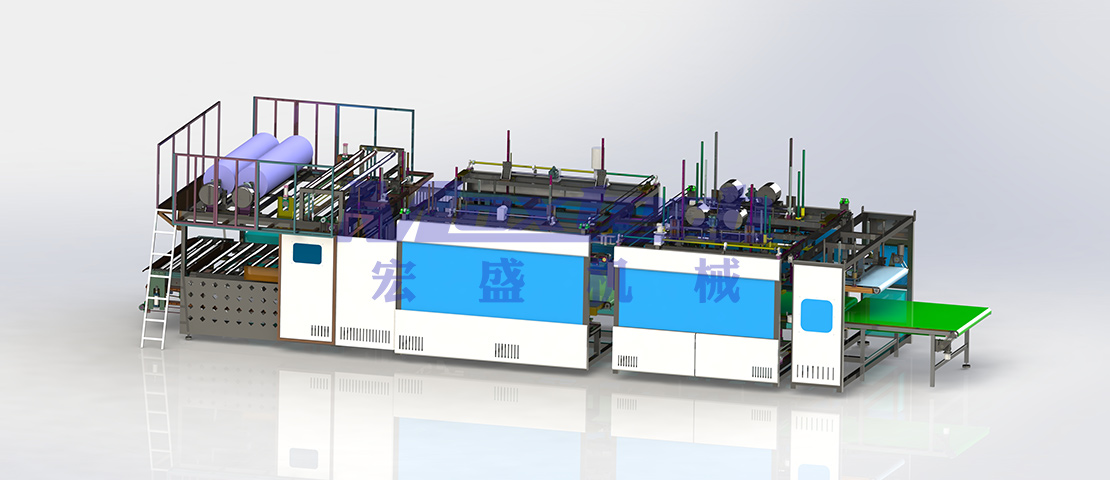

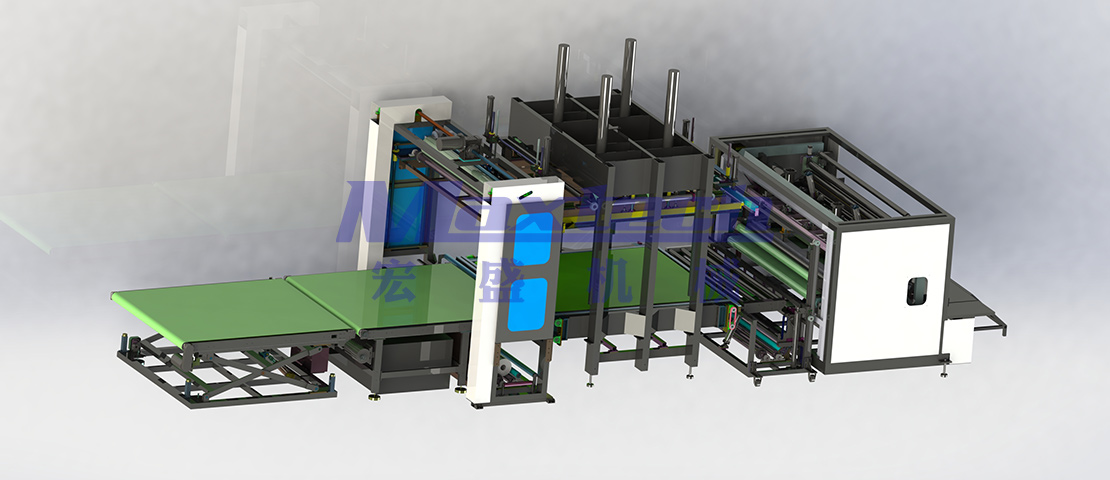

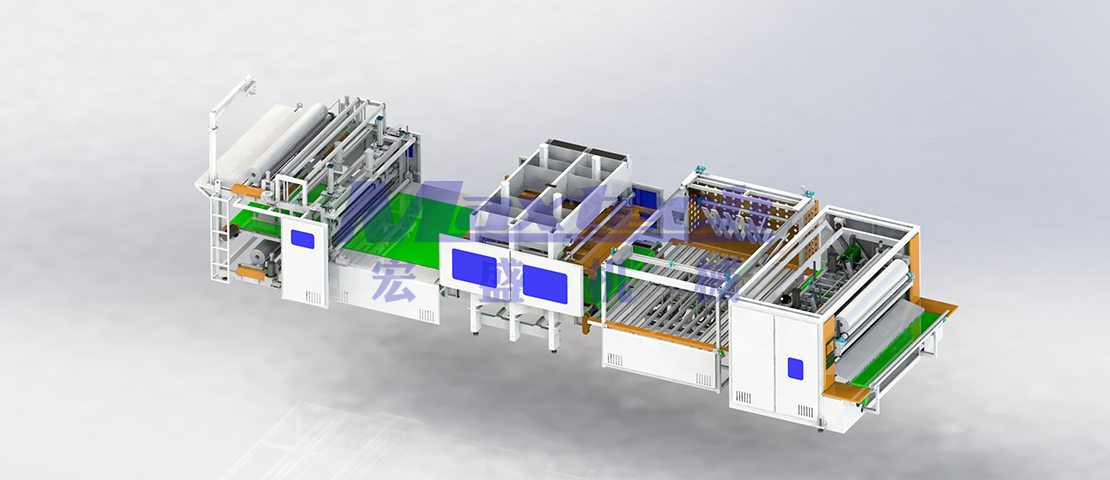

Working Principle:The mattress is fed into the equipment by the roller line and accurately positioned by photoelectricity. The motor pulls the entire tooling up and down for stacking and positioning, and the whole chopped mattresses are stacked through the synchronous belt and the roller line relative reverse conveying.

Product features:

①.Ring form power conveying structure, stable power transmission, smooth up and down lifting movement, synchronous action;

②.Linear guide for guidance, stable movement, long service life;

③.There is a pallet limit on the bottom, and a rear limit on the tooling, which makes the stack more neat and easy to operate and place;PLC intelligent control, can achieve a variety of intelligent distribution of multiple units.The mattress stacking machine can be equipped with a production line. For example, it is configured on the back side of the gluing machine line, the back side of the automatic edge tape machine, the back side of the automatic packing machine,the back side of the automatic sponge trimming machine to achieve automatic stack.

Maximum mattress size | 2200*2200mm |

Maximum height | 2200mm |

Production efficiency | 30s/1pcs |